板带矫平机

Strip Leveling Machine

.png)

.png)

.png)

.png)

| 型号 Model | C783-2/ZF型 | C785/ZF型 | C782型 | C782/ZF型 | C782-1/ZF型 |

| 矫平辊数 Qty of leveling rolls | 7辊 7 rolls | 13辊 13 rolls | 15辊 15 rolls | 17辊 17 rolls | 19辊 19 rolls |

| 矫平辊直径 Diameter of leveling rolls | Φ60mm | 90mm | 50mm | 45mm | 12mm |

| 矫平宽度 Leveling width | 260mm | 1000mm | 600mm | 1000mm | 150mm |

| 矫平厚度 Leveling thickness | 0.3~3mm | 2~6mm | 0.3~2mm | 0.3~2mm | 0.2~1.0mm |

| 矫平速度 Leveling speed | 10m/min | 10m/min | 14m/min | 14m/min | 10m/min |

| 電(diàn)机功率 Motor power | 3KW | 37KW | 7.5KW | 11KW | 1.1KW |

用(yòng)途 Application

矫平机用(yòng)于对带料厚度,屈服强度不大于δs260Mpa的钢板或有(yǒu)色金属板材的矫平。

This machine is used to level steel plate or non-ferrous plate (thickness 0.3~2mm/2~6mm, yield strength ≤s260Mpa)

设备组成 Equipment composition

矫平机主要由过料板、矫直装置、动力装置、底座等组成。

It is mainly composed of feeding plate、leveling device、base and so on.

飞剪机

Flying Shear Machine

.png)

.png)

.png)

用(yòng)途 Application

本飞剪机组用(yòng)于将金属带料沿横向进行分(fēn)切,将剪切后的板带码齐,堆垛。机组采用(yòng)全数字交流变频调速系统,PLC及全液压控制,单机调整与全線(xiàn)自动运行控制全部集中于控制台上。

The flying shear machine is used to cut the metal belt transversely and place the slitted belts neatly and stack. This machine has all-digital AC variable frequency speed adjust system, PLC and full hydraulic control. There are single-machine adjustment and all-line automatic operation on the control panel.

主要参数 Technical parameters

1.材质:锡青铜、白铜、紫铜、黄铜、高铜合金(150Mpa≤σb≤850Mpa 5%≤δ5≤50%)

Material: tin bronze, cupronickel, red copper, brass, high copper alloy(150Mpa≤σb≤850Mpa 5%≤δ5≤50%)

2. 原料规格 Material specifications:

厚度 Thickness: 0.5~3.5mm

宽度 Width: 300~660mm

内径 ID: Φ610mm

外径 OD: ≤Φ1800mm

卷重 Roll weight: ≤10t

3. 成品规格 Products specifications:

長(cháng)度 Length: 500~3500mm

最大堆垛高度 Max. stacking height: 600mm

最大堆垛重量 Max. stacking weight: 10000kg/垛 stack

4.成品参数 Products parameters:

長(cháng)度公差 Length tolerance: ≤±0.7mm

对角線(xiàn)公差 Diagonal tolerance ≤±1.0mm

平直度 Glancing flatness ≤3mm

剪切片数 Shear pieces ≤60 pieces/min (按2.0mm,成品長(cháng)度500mm 2.0mm,products length 500mm)

5. 机组工艺方案及参数 Machine technique plan and parameters:

机组方向 暂定从左向右 (从操作者面向机组)

Machine direction From left to right (the operator faces the machine)

穿带速度 Threading speed 15m/min

机组最大速度 Max. working speed 80m/min

开卷最大张力 Max. uncoiling tension 6.8KN

机组开卷方式 Uncoiling way 向上 up

液压系统压力 Hydraulic system pressure ≤12Mpa

机组占地面积 Floor area: 長(cháng)约 Length 21m,宽约 Width 9m,高约 Height 2.5m

机组装机水平及特点 The installation level and features

1.机组采用(yòng)PLC控制,具有(yǒu)工艺过程参数的设定、监测、显示、電(diàn)气联锁、故障报警等功能(néng)。

2.電(diàn)气自动化系统有(yǒu)过载保护、断路保护、急停功能(néng)等安全保护措施。

3.开卷机、牵引矫平机采用(yòng)全数字交流变频调速,定尺机采用(yòng)变频電(diàn)机控制。

4.机组采用(yòng)全数字交流变频调速控制系统,電(diàn)机维护简单方便。

1. The machine adopts PLC control and has the functions of the parameters setting, monitoring, showing, electric interlock, error warning and so on.

2. The electrical automation system has the safety measures such as the overload protection, the circuit break protection, the emergency stop and so on.

3. The uncoiling and the traction leveling machines use all-digital AC variable frequency speed adjustment. The shear gauge is controlled by the variable frequency motor.

4. The machine uses all-digital AC variable frequency speed adjust system. It is easy to maintain the motor.

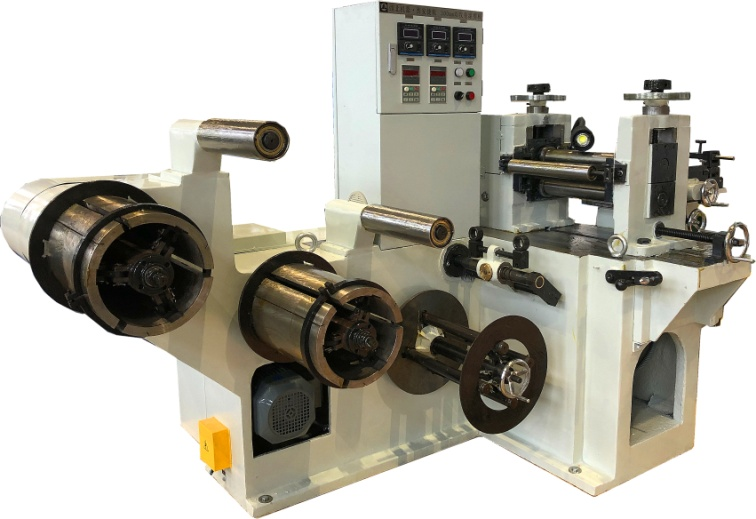

80mm双收卷滚剪机(C80035/ZF型)

80mm Double Winding Slitting Mill(C80035/ZF)

用(yòng)途 Application

本滚剪机适用(yòng)与金属带料的纵向剪切工作,并且将分(fēn)切后的窄条重新(xīn)卷绕成卷。本机具有(yǒu)操作方便,切割质量高,材料利用(yòng)率高。

This machine is applied to slit the metal belt longitudinally and wind the slitted strips. This machine is operated easily. It can slit in high quality and has high material utilization rate.

主要技术参数 Main technical parameters

剪切带料厚度 Belt slitting thickness 0.03mm~0.35mm

剪切宽度 Slitting width Max80mm

原料外径 Material OD MaxΦ400m

原料卷重量 Material reel weight Max50KG

剪切宽度 Slitted strip width: Min1mm

刀(dāo)具尺寸 Blade size Φ25mm×Φ60mm×B

切割速度 Slitting speed 15mmin(variable frequency speed control)

切割条数 Slitting strips 12 strips

剪切精度 Slitting precision width ±0.02mm camber ≤1mm/M

收卷内径 Winding ID: Φ80mm

電(diàn)机 Motor 0.75KW

设备净重 Machine net. weight 900KG

150mm双收卷滚剪机(C8005-4/ZF型)

150mm Double Winding Slitting Mill(C8005-4/ZF)

用(yòng)途 Application

本滚剪机适用(yòng)与金属带料的纵向剪切工作,并且将分(fēn)切后的窄条重新(xīn)卷绕成卷。本机具有(yǒu)操作方便,切割质量高,材料利用(yòng)率高等优点。

This machine is suitable for applied to slit the metal belt longitudinally and wind the slitted strips. This machine is operated easily. It can slit in high quality and has high material utilization rate.

主要技术参数 Main technical parameters

剪切带料厚度 Belt slitting thickness 0.05mm~0.5mm

剪切宽度 Slitting width Max150mm

原料外径 Material OD MaxΦ300mm

原料卷内径 Material ID Φ200mm

原料卷重量 Material reel weight Max300KG

剪切宽度 Slitted strip width Min3mm(0.4mm以下 less 0.4mm)

刀(dāo)具尺寸 Blade size Φ40mm×Φ105mm×B

切割速度 Slitting speed 5~20m/min(变频调速 variable frequency speed control)

切割条数 Slitting strips 12 条 strips(按普碳钢考核 based on plain carbon steel)

剪切精度 Slitting precision 宽度 width±0.03mm 镰刀(dāo)弯 camber≤1mm/M(最小(xiǎo)宽度10mm考核 based on Min. width 10mm)

收卷内径 Winding ID Φ120mm

電(diàn)机 Motor 1.5KW

300mm双收卷滚剪机(C8008-3/ZF型升级版)

300mm Double Winding Slitting Mill(C8008-3/ZF Upgrade)

用(yòng)途 Application

适用(yòng)于金属带料的纵向剪切工作,并且将分(fēn)切后的窄条重新(xīn)卷绕成卷。本机具有(yǒu)操作方便,切割质量高,材料利用(yòng)率高,切割速度无级可(kě)调等优点。

This machine is suitable for applied to slit the metal belt longitudinally and wind the siltted strips. This machine is operated easily. It can slit in high quality and has high material utilization rate.

主要技术参数 Main technical parameters

剪切带料厚度 Belt slitting thickness 0.05mm~0.5mm (有(yǒu)色金属达 non-ferrous metals 0.8mm)

剪切宽度 Slitting width Max305mm

原料外径 Raw material OD MaxΦ800mm

原料卷内径 Raw material ID Φ250mm~Φ520mm

原料卷重量 Raw material reel weight Max750KG

剪切宽度 Slitted strip width Min 3mm(厚度0.4mm以下 thickness is less than 0.4mm)

刀(dāo)具尺寸 Blade size Φ60mm×Φ125mm×B

切割速度 Slitting speed 60m/min(交流变频无级调速 AC variable frequency stepless speed control)

切割条数 Slitting strips 12 条 strips(按普碳钢考核 based on plain carbon steel)

剪切精度 Slitting precision 宽度 width±0.05mm 镰刀(dāo)弯 camber≤1mm/M(最小(xiǎo)宽度10mm考核 based on Min. width 10mm)

收卷内径 Take-up ID: Φ150mm ;Φ250mm

電(diàn)机 Motor: 剪切 slitting 1.5KW;收卷 take-up 2.2KW

设备净重 Machine Net. weight : 3000KG

450mm双收卷滚剪机(新(xīn)型)

450mm Double Winding Slitting Mill(New)

用(yòng)途 Application

450mm滚剪机适用(yòng)与金属带料的纵向剪切工作,并且将分(fēn)切后的窄条重新(xīn)卷绕成卷。操作方便,切割质量高,材料利用(yòng)率高,切割速度可(kě)调。

This machine is suitable for applied to slit the metal belt longitudinally and wind the siltted strips. This machine is operated easily. It can slit in high quality and has high material utilization rate.

主要技术参数 Main technical parameters

剪切带料厚度 Belt slitting thickness 0.1mm~1.0mm

剪切宽度 Slitting width Max450mm

原料外径 Raw material OD MaxΦ800mm

原料卷内径 Raw material ID Φ250mm~Φ510mm (加增径板 add the diameter increasing plate)

原料卷重量 Raw material reel weight Max1000KG

剪切宽度 Slitted strip width Min5mm(0.8mm以下 thickness is less than 0.8mm)

刀(dāo)具尺寸 Blade size Φ80mm×Φ160mm×B

切割速度 Slitting speed 1 0m~60m/min

切割条数 Slitting strips 12条strips(0.8mm以下考核 based on less than 0.8mm)

剪切精度 Slitting precision 宽度 width ±0.05mm

镰刀(dāo)弯 Camber ≤1mm/M

收卷内径 Take-up ID Φ250mm (卷筒可(kě)手动涨缩 manual swelling and shrinking)

收卷外径 Take-up OD Φ700mm (Max)

剪切電(diàn)机 Motor for slitting AC motor 4KW

收卷電(diàn)机 Take-up motor: AC motor 5.5KW

设备净重 Machine Net. weight about4500KG

设备尺寸 Machine dimension 長(cháng) length 6500mm×宽 width 2500mm×高 height 1800mm

0.8~3.5×670mm纵剪机组

0.8~3.5×670mm Slitting Unit

.png)

.png)

.png)

机组简介 Brief introduction

0.8~3.5×670mm纵剪生产線(xiàn)采用(yòng)全数字交流变频调速系统,PLC及全液压控制,对金属带料进行纵剪后,再按一定的张力卷绕成卷。剪切速度,卷取電(diàn)流,長(cháng)度设定,单机调整与全線(xiàn)运行控制全部集中于控制台上。

0.8~3.5×670mm slitting unit adopts AC motor speed control system, PLC and full-hydraulic control. The machine unit is applied for slitting the metal strip, and then rewinds the strip according to the certain winding tension. The slitting speed, the coiling current, the length setting, the single machine adjustment and automatic running control are all collected in the console.

主要参数 Main parameters

1. 生产材料: 紫铜 框架铁铜 青黄铜(σb =150~500Mpa、δ5 = 8-25%)

Material red copper, frame iron and copper, bronze and brass(σb =150~500Mpa、δ5 = 8-25%)

2. 来料规格 Material specifications

厚度 Thickness 0.8~3.5mm

0.8~2.0mm 硬态 hard state σb =250~500Mpa δ5 = 8-15%

2.0~3.5mm 软态 soft state σb =150~300Mpa δ5 = 10-25%

宽度 Width 200mm~670mm

表面平整度 Surface evenness ≤1.5mm/mm

料卷内径 The roll ID Φ500mm、Φ610mm(加增径板 add the diameter increasing plate)

料卷外径 The roll OD ≤ Φ1500mm

卷重 Weight of the material roll ≤ 8.5T

3. 产品规格 Products parameters

厚度 Thickness 0.8~3.5mm

料卷内径 The roll ID Φ400mm、Φ500mm(加增径板 add the diameter increasing plate)

料卷外径 The roll OD ≤Φ1500mm

卷重Weight of the roll ≤8T

4. 剪切技术性能(néng) Slitting technical features

剪切条数及速度 Slitting strips and speed 0.8~1.5mm ≤25 条 strips ≤100m/min

1.5~2.0mm ≤15 条 strips ≤100m/min

2.0~3.5mm ≤8 条 strips ≤60m/min

剪切宽度公差 Width tolerance 0.8~2.0mm ≤ ±0.05mm

2.0~3.5mm ≤ ±0.10mm

带料侧弯 Side bend 0.8~2.0mm ≤1mm/m

2.0~3.5mm ≤1.5mm/m

剪切毛刺 Burr 硬态≤料厚的4%;软态≤料厚的3%

hard state ≤ 4% thickness;soft state ≤ 3% thickness

最小(xiǎo)分(fēn)切宽度 Min. cutting width 25mm

带卷错层公差 Layer offset tolerance ≤ ±1mm

带卷塔形公差 Pyramid tolerance ≤ ±2mm(带卷内外各5圈除外 except for inside and outside 5 rounds each)

5. 机组工艺方案及参数 Process parameters of the unit

机组方向 Unit direction 暂定从左向右 (从操作者面向机组)

provisional direction is from left to right (the operator faces the unit)

作业線(xiàn)标高 Operation line height +900 mm

穿带速度 Threading speed 20m/min

机组最高速度 Max. speed of the unit 100m/min (based on 600mm)

开卷最大张力 Max. tension of uncoiling 6KN

卷取最大张力 Max. tension of coiling 26KN

剪切工作方式 Way of slitting 主动剪切 Active slitting

机组开卷方式 Way of uncoiling 上开卷 up

机组卷取方式 Way of coiling 下卷取 down

机组占地面积 Floor area 長(cháng)约21m,宽约9m,高约2.5m

Length about 21m,width about 9m,height about 2.5m

机组装机水平及特点 The installation situation and features

1. 机组采用(yòng)PLC控制。开卷机、牵引横剪机、纵剪机、卷取机采用(yòng)全数字交流变频调速。

2. 電(diàn)气自动化系统有(yǒu)过载保护、断路保护、急停功能(néng)等安全保护措施。

3. 机组具有(yǒu)工艺过程参数和设备关键参数的监测和报警系统。机组電(diàn)气联锁、故障报警采用(yòng)PLC控制。

4. 圆盘剪上刀(dāo)轴提升及活动牌坊移动均采用(yòng)電(diàn)机驱动,通过调换组合式隔套,可(kě)灵活改变剪切的成品宽度要求。

1. The uncoiler, the traverse cutting machine, the slitting mill and the coiler has the all-digital AC variable frequency speed adjustment. The machine unit adopts PLC control.

2. The electrical automation system has the safety measures such as the overload protection, the circuit break protection, the emergency stop and so on.

3. The machine unit can monitor and display the process parameters and the key equipment parameters. The electric interlock and the error warning uses PLC control.

4. The lifting for circle shears for upper shaft and the active memorial archway are driven by the motor. By exchanging the combined spacer bushes, it can change the width of the slitted products flexibly.

650mm薄带纵剪机组

650mm Thin Strip Slitting Machine Unit

.png)

.png)

.png)

1. 用(yòng)途 Application

本机组用(yòng)于将金属带料沿纵向进行分(fēn)切,并将分(fēn)切后的带料按一定的张力重新(xīn)卷绕成卷。机组采用(yòng)全数字交流变频调速系统,PLC及全液压控制,单机调整与全線(xiàn)自动运行控制全部集中于控制台上。

The machine unit is applied for slitting the metal strip, and then rewinds the strip according to the certain winding tension. The unit adopts AC motor speed control system. PLC and hydraulic control, the single machine adjustments, and automatic running control are all collected in the console.

2. 主要参数 Main parameters

(1) 材质: 不锈钢、紫铜等(150Mpa≤σb≤850 Mpa,8%≤δ5≤40%)

Material stainless steel, red copper etc.(150Mpa≤σb≤850 Mpa,8%≤δ5≤40%)

(2) 原料规格 Material specifications

厚度 Thickness 0.05~0.5mm

宽度 Width 300~650mm

内径 ID Φ610mm

外径 OD ≤Φ1650mm

卷重 Weight of the material roll ≤8t

(3) 成品规格 Products specifications

内径 ID Φ300mm、Φ400mm、Φ500mm

外径 OD ≤Φ1650mm

卷重 Weight of the material roll ≤8t

(4) 成品参数 Products parameters

剪切条数 Slitting strips ≤30 条 strips

剪切速度 Slitting speed ≤180m/min

毛刺 Burr ≤0.02mm; ≤0.03mm

宽度公差 Width tolerance 宽度 width>100mm ±0.10mm

宽度 width≤100mm ±0.05mm

侧弯 Side bend ≤1mm/m

错层公差 Layer offset tolerance ≤±0.2mm(内外各5圈除外 except for inside and outside 5 rounds each)

塔形公差 Pyramid tolerance ≤±1mm(内外各5圈除外 except for inside and outside 5 rounds each)

(5) 机组工艺方案及参数 Process parameters of the unit

机组方向 Unit direction 待定(从操作者面向机组) To be confirmed (the operator faces the unit)

穿带速度 Threading speed 20m/min

机组最大速度 Max. speed of the unit 180m/min(按Φ610mm以上直径考核 based on ≥Φ610mm)

卷取最大张力 Max. tension of coiling 6KN

剪切工作方式 Way of slitting 主动剪切 Active slitting

机组开卷方式 Way of uncoiling 上开卷 up

机组卷取方式 Way of coiling 上卷取 up

液压系统压力 Hydraulic system pressure ≤12Mpa

机组占地面积 Floor area 長(cháng)约16.5m,宽约9m,高约2.5m

Length about 16.5m,width about 9m,height about 2.5m

3. 机组装机水平及特点 The installation situation and features

(1)开卷机、纵剪机、卷取机采用(yòng)全数字交流变频调速,机组采用(yòng)PLC控制。

(2)電(diàn)气自动化系统有(yǒu)过载保护、断路保护、急停功能(néng)等安全保护措施。

(3)机组具有(yǒu)工艺过程参数和设备关键参数的监测、显示。机组電(diàn)气联锁、故障报警采用(yòng)PLC控制。

(4)圆盘剪采用(yòng)双偏心结构,手动调节偏心量。通过调换组合式隔套,可(kě)灵活改变剪切的成品宽度要求

(1) The uncoiler, the slitting machine and the coiler has the all-digital AC variable frequency speed adjustment and PLC control.

(2) The electrical automation system has the safety measures such as the overload protection, the circuit break protection, the emergency stop and so on.

(3) The machine unit can monitor and display the process parameters and the key equipment parameters. The electric interlock and the error warning uses PLC control.

(4) The circle shear adopts the double eccentric structure, which can adjust the eccentricity manually. By exchanging the combined spacer bushes, it can change the width of the slitted products flexibly.

650mm森吉米尔型二十辊轧机

650mm Sendzimir 20 Rolls Mill

-1024x772.png)

.png)

用(yòng)途 Application

650mm森吉米尔型二十辊轧机是在常温状态下,将厚度為(wèi)Max1.2mm的不锈钢,经若干道次轧制,轧制成各类规格的具有(yǒu)所需厚度和表面粗糙度的冷轧带卷。

650mm 20 rolls Sendzimir Cold Mill is used to roll Max. 1.0mm thickness stainless steel at normal temperature state to the cold rolled strip coils of different thickness and surface roughness.

性能(néng)指标 Technical data

1. 来料规格 Materials specifications

1)入口重卷段 Entry recoiling parameters

材料 Material SUS200、SUS300不锈钢 stainless steel

来料状态 Material state 退火冷轧料 Annealing cold rolled material

宽度 Width 450-750mm

厚度 Thickness 0.08-1.2mm

卷径 Coil diameter Φ508/Φ1000-Φ1800mm (含衬纸 including the lining paper)

卷重 Coil weight Max 12600kg

2)轧制段 Rolling part

材料 Material SUS200、SUS300 不锈钢 stainless steel

来料状态 Material state 退火冷轧料 Annealing cold rolled material

宽度 Width 450-650mm

厚度 Thickness 0.08-1.2mm

卷径 Coil diameter MaxΦ1800mm (含衬纸 including the lining paper)

卷重 Coil weight Max 11000kg

2. 成品规格 Product specification

1) 轧制段 Rolling part

宽度 Width 450-650mm

厚度 Thickness 0.05-0.3 mm

卷径 Coil diameter MaxΦ1800mm (含衬纸 including the lining paper)

卷重 Coil weight Max 11000kg

2)出口重卷段 Outlet recoiling part

宽度 Width 450-750mm

厚度 Thickness 0.05-0.3 mm

卷径 Coil diameter Φ508/Φ1000-Φ1800mm (含衬纸 including the lining paper)

卷重 Coil weight Max 12600kg

技术参数 Technical parameters

1. 入口重卷参数 Entry recoiling parameters

高速段 High speed period Max 190m/min 张力范围 tension range 1.44~14.4KN

低速段 Low speed period Max 110m/min 张力范围 tension range 2.4~24KN

卷筒 Reel Φ508×850mm

减速机速比 Speed ratio of the reducer 16.87/10.12

传动電(diàn)机 Driving motor DC67KW,0-450-1500r/min, 400V 风冷air cooling

2. 左右卷取参数 Parameters of coiling left and right

低速段 Low speed period Max 180m/min 张力范围 tension range 13.5~135KN

高速段 High speed period Max 300m/min 张力范围 tension range 6.5~65KN

卷筒 Reel Φ500x850mm

减速机速比 Speed ratio of the reducer 10.22/4.92

传动電(diàn)机 Driving motor DC500KW, 0-362-1200 r/min,440V,水-空冷却 water-air cooling

3. 轧机参数 The rolling mill parameters

工作辊直径 Working roll diameter Φ45mm

第一中间辊直径 The first intermediate roll diameter Φ71.4mm

第二中间辊直径 The second intermediate roll diameter 辊子直径 the roll diameter Φ127.8mm

背衬辊轴承 The backing roll bearing Φ225mm

最大轧制力 Max. roll force 2000KN

轧制扭矩 Rolling torque 11.5KN·M/5.7KN·M

轧机开口度 The rolling mill opening 3.25mm(公称轧辊直径时,轧辊直径减小(xiǎo),开口度增大 when in the normal roll diameter,the roll diameter decreases and the opening increases)

轧制速度 Rolling speed Max 300m/min

减速机速比 Speed ratio of the reducer 1

轧机传动電(diàn)机 The rolling mil driving motor DC500KW, 0-362-1200 r/min,440V,水-空冷却 water-air cooling

4. 出口重卷参数 Outlet recoiling parameters

速度 Speed 190m/min 张力范围 tension range 1.26~12.6KN

卷筒 Reel Φ508x850mm

减速机速比 Speed ratio of the reducer 12.38

传动電(diàn)机 Driving motor DC49KW,0-450-1500r/min,400V

450mm森吉米尔型二十辊轧机

450mm Sendzimir 20 Rolls Mill

-782x1024.png)

-1024x802.png)

机组用(yòng)途 Application

450mm森吉米尔型二十辊轧机是在常温状态下,将厚度為(wèi)1.0mm的带材,经若干道次轧制,轧制成各类规格的具有(yǒu)所需厚度和表面粗糙度的冷轧带卷。

450mm 20 rolls Sendzimir Cold Mill is used to roll the 1.0mm thickness stainless steel at normal temperature state to the strip coils of different thickness and surface roughness.

性能(néng)指标 Technical data

1. 来料规格 Materials specifications

材料 Material SUS200、SUS300、SUS400不锈钢 stainless steel (σb=515MPa)

来料状态 Material state 退火冷轧料 Annealing cold rolled material

宽度 Width 250-450 mm

厚度 Thickness Max 1.0mm

卷外径 OD MaxΦ1800mm (含衬纸 including the lining paper)

卷内经 ID Φ508mm

卷重 Coil weight 8000kg

2. 成品规格 Product specification

宽度 Width 250-450mm

厚度 Thickness ≥0.06mm

卷外径 OD MaxΦ1800mm(含衬纸 including the lining paper)

卷内经 ID Φ508mm

卷重 Coil weight 8000kg

3. 成品厚度公差(稳速段) Product thickness tolerance(steady speed part)

| 成品厚度 Product thickness(mm) | 厚度公差 Thickness tolerance (mm) | 公差范围内的轧制長(cháng)度保证值 Guarantee value for mill length within the tolerance range |

| 0.5<h | ±1%h | ≥98% |

| 0.3≤h≤0.5 | ±0.005 | ≥98% |

| h≤0.3 | ±0.003 | ≥98% |

4. 成品板形公差 The sheet shape tolerance: ≦20IU

技术参数 The technical parameters

1. 原料重卷参数 Raw material recoiling parameters

速度 Speed 220m/min

卷筒 Reel Φ508×500mm

张力 Tension 11KN

减速机速比 Speed ratio of the reducer 11.3

传动電(diàn)机 Driving motor Z4-250-31 DC49KW,0-450-1500r/min 400V

2.左右卷取参数 Parameters of coiling left and right

卷筒 Reel Φ500×500mm

减速机速比12时 速度Max220m/min 张力Max70KN

Speed ratio of the reducer is 12, speed Max220m/min, Tension Max70KN

减速机速比7.55时 速度Max350m/min 张力Max44KN

Speed ratio of the reducer is 7.55, speed Max350m/min, Tension Max44KN

传动電(diàn)机 Driving motor Z400-4A,315KW,0-467-1500r/min,440V

3.轧机参数 The rolling mill parameters

工作辊尺寸 Working roll diameter Φ35X517mm

第一中间辊尺寸 The first intermediate roll diameter Φ51X560mm

第二中间辊尺寸 The second intermediate roll diameter Φ90X517mm

背衬辊轴承 The backing roll bearing Φ160mmXΦ70mm

最大轧制力 Max. roll force 1200KN

最大轧制速度 Max. roll speed 220/350m/min

减速机速比 Speed ratio of the reducer 1

传动電(diàn)机 Driving motor Z400-4A,315KW,0-467-1500r/min,440V

工艺润滑冷却流量(矿物(wù)油)Technical lubrication cooling flow rate(mineral oil) 1800L/min

4. 成品重卷参数 Product recoiling parameters

速度 Speed 220m/min

卷筒 Reel Φ508×500mm

张力 Tension 15KN

减速机速比 Speed ratio of the reducer 11.3

传动電(diàn)机 Driving motor Z4-250-42 DC67KW,0-450-1500r/min 400V

260mm森吉米尔型二十辊轧机

260mm Sendzimir 20 Rolls Mill

机组用(yòng)途 Application

260mm森吉米尔型二十辊轧机是在常温状态下,将厚度為(wèi)0.6mm的带材,经若干道次轧制,轧制成既定规格的具有(yǒu)所需厚度和表面粗糙度的冷轧带卷。

260mm 20 rolls Sendzimir Cold Mill is used to roll the 0.6mm thickness stainless steel at normal temperature state to the strip coils of different thickness and surface roughness.

性能(néng)指标 Technical data

1. 来料规格 Materials specifications

材料 Material SK5(if 0.6mm, σb≤1800MPa,if 0.1mm, σb≤2400MPa)

来料状态 Material state 冷轧料 Cold rolled material

宽度 Width 200-230mm

厚度 Thickness Max 0.6mm

卷外径 OD MaxΦ1200mm

卷内经 ID Φ508mm

卷重 Coil weight 2000Kg

2. 成品规格 Product specification

宽度 Width 200-230mm

厚度 Thickness Min0.1mm

卷外径 OD MaxΦ1200mm

卷内经 ID Φ508mm

卷重 Coil weight 2000Kg

3. 成品厚度公差(稳速段)Product thickness tolerance(steady speed part)

| 成品厚度 Product thickness (mm) | 厚度公差 Thickness tolerance (mm) | 公差范围内的轧制長(cháng)度保证值 Guarantee value for mill length within the tolerance range |

| ≤0.2 | ±0.003 | ≥96% |

| 0.2-0.4 | ±0.005 | ≥96% |

技术参数 The technical parameters

1. 入口重卷参数 Entry recoiling parameters

速度 Speed Max100m/min (above Φ540 mm)

卷筒 Reel Φ508×280mm

张力 Tension 18KN

减速机速比 Speed ratio of the reducer 17.5

传动電(diàn)机 Driving motor Z4-225-11,DC40KW,0-540-1200r/min,400V

2.左右卷取参数 Parameters of coiling left and right

卷筒 Reel Φ500×280 mm

减速机速比 Speed ratio of the reducer 13.5

张力 Tension Max 65KN

速度 Speed Max 140m/min

传动電(diàn)机 Driving motor Z4-315-31,118KW,0-360-1200r/min,400V

3.轧机参数 The rolling mill parameters

工作辊尺寸 Working roll diameter Φ25-Φ19.5×304 mm

第一中间辊尺寸 The first intermediate roll diameter Φ42-Φ37×372 mm

第二中间辊尺寸 The second intermediate roll diameter Φ72-Φ67×304 mm

背衬辊轴承 The backing roll bearing Φ55×Φ120 mm

最大轧制力 Max. roll force 800KN

轧制速度 Roll speed Max 140m/min

减速机速比 Speed ratio of the reducer 1

轧机传动電(diàn)机 The rolling mill driving motor Z4-355-11,166KW,0-360-1200r/min,400V

工艺润滑冷却流量(矿物(wù)油) Technical lubrication cooling flow rate (mineral oil 800L/min)